Care, attention and consideration are the basis of the whole process of creating a garment, a work of precision divided into three large acts performed with their fingertips.

Act one: the material

The jacket is a living object, it breathes and adapts to the environment and weather conditions. The raw material has unique characteristics and comes from the processing of the best fibers available on the market, processed with accuracy and transformed into fine fabrics that Canali selects exclusively from the best wool mills in the world.

It is through the choice of fabric, pattern and color that the definition of the character of a jacket begins. Because the fabric represents the first chapter of the story that every jacket, when worn, tells. Just like people who stand out for their charisma, inventiveness, and passion, to the point of becoming capable leaders, the fabric in the jacket symbolizes the set of characteristics that make it special and unique.

Act two: the creation

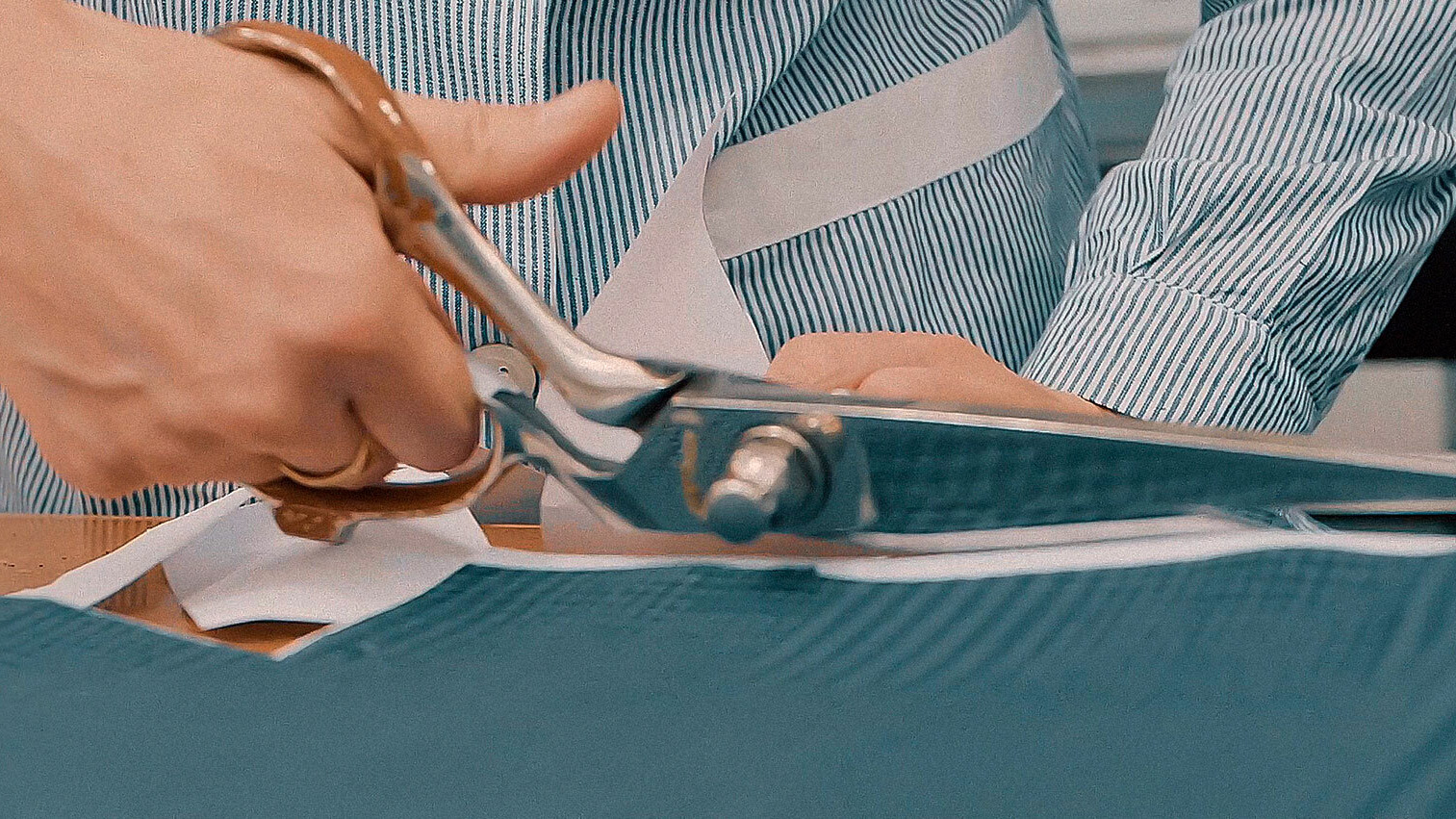

Each portion of fabric, which is cut and prepared to be processed, is entrusted to the hands, precise hands, which have to perform a part of the long process that culminates in the finished jacket with care and sensitivity. It is a great puzzle recreated through a series of small steps where many different parts take shape and join together: the front, the sleeves and collars, the hips, the back, the lapel facing with the inner pockets, the lining.

Each component is added to the other, in a process that in some models accounts up to 200 steps. A sum whose final value is much higher than that of single elements.

The construction of a jacket starts from its front. First, a reinforcement is created, to give substance and shape to the skeleton that will support the garment.

Then the pockets enter the scene, the shape is outlined, one or more layers are added to give them support, then the lining is applied. Then the pockets are sewn and shaped through ironing, then stitched to give harmony and embellish the seams, and finally applied to the jacket.

The tacking of the front part of the jacket is a fundamental step because inside is the lapel facing, a part composed of several layers that support the front and keep it “in shape.” This is a distinctive feature of a Canali sartorial jacket, which is still made by assembling different parts one by one, as they are joined together at the seams. In this way, the jacket has the necessary structure to accompany the movements of the body, always remaining impeccable.

In the end, the last protagonist of the front enters the scene, the element that perhaps most of all encloses the character and style of the jacket: the lapel. Its shape is built through a set of seams that define the harmonious line, determine the lapel and movement, and allow it to adhere to the canvas.

After completing the front, it is time for the hips and back, and as for the front, these components are first basted with seams that have the task of joining the various parts, then they are lined, sewn together, shaped through ironing and finished through stitching.

Now the jacket is composed of almost all its main elements, only one step is missing to complete the garment: sewing the sleeves.

A passage in which the craftsman’s skill is able to create a three-dimensional sleeve from a two-dimensional fabric. This happens thanks to the looseness, a set of curled seams, which have the task of giving mobility and elasticity to the movement of the entire sleeve.

A skill achieved through years of experience, to acquire the ability and the right sensitivity in distributing a fabric’s looseness. The result is a sleeve with soft and clean lines that offers an extremely comfortable fit.

Act three: the final test

The jacket, in its entirety, is now almost finished.

The last ironing, unlike the previous phases in which ironing serves to give a precise shape and structure, aims to restore harmony to the fabric’s fibers, and to define the lines of the garment that is now ready for the final test.

This last phase is performed accurately, manually. This is the moment when it is verified that the whole process has been carried out correctly. For each garment, length, sizes and measurements are checked.

The geometry of the textures, the integrity of the fabric and the execution of the processing are examined.

The hands of those who know every inch, every seam, but also the attentive eyes of those who have the ability to find every little imperfection deal with this important step.

The long job of creating a jacket is now complete. The three-act opera has concluded, but it is not yet time for the curtain to drop.

The jacket is now ready to be worn, to find its leading actor, and to start telling its story.